Graphics

Award Winning Graphics

Our award winning graphics and plate department is a pioneer in the use of water

washed plate systems, as well as direct to plate technology. We use the Kodak

Insite proofing system to speed up customer approvals. This web portal system

provides soft proof approval for customers online by automatically documenting

requested changes. Unlike PDF proofs, Insite is a direct proof from the actual

production file, and thereby improves the product to market timeline. As the

original North American Beta test site for Asahi AWP water washed plate system

since 2012, our plates have improved printing attributes through more consistent

surface tension, resulting in improved highlight details on every package we

produce. Capable of being washed in soap and water, our plates require less

frequent plate cleaning on press and help keep our companies carbon footprint to

a minimum.

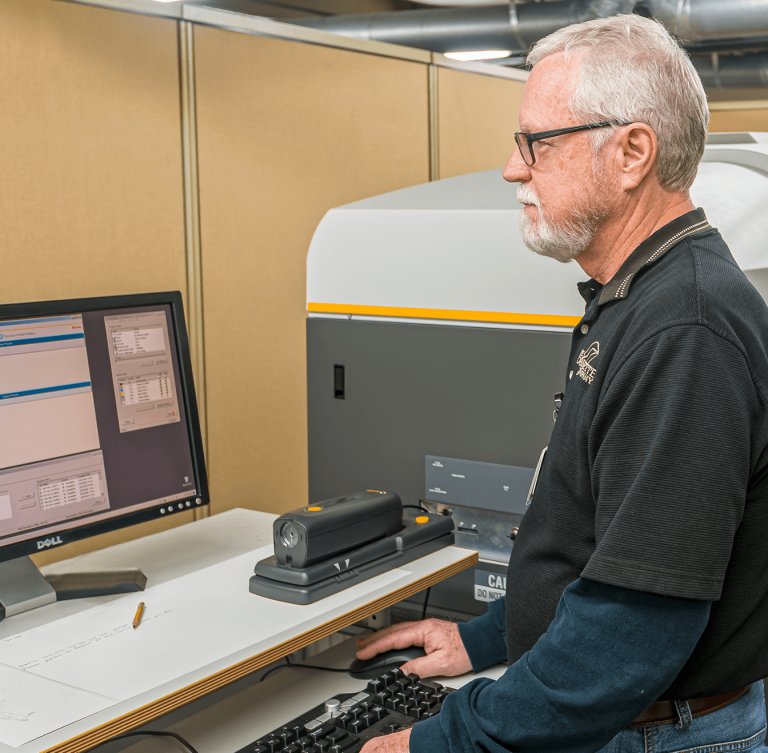

Prinergy PowerPack Workflow

Our experience and knowledge of Prinergy PowerPack Workflow means we know how to get the most out of this powerful tool and produce outstanding results for our customers. Combining best-in-class performance, reliability, productivity, and connectivity options, we utilize the best equipment to deliver quality work every time.

Kodak InSite Approval System

By streamlining job submission, collaboration, and proofing for customers, KODAK INSITE Prepress Portal efficiently manages the prepress process while minimizing errors, unexpected costs, and delays. Our clients can see exactly where their package or print job is in the production process; giving them the ability to track progress, collaborate on changes, and review and approve work—anywhere, anytime.

ThermoFlex Computer To Plate System

Our ThermoFlex Computer to plate (CTP) system helps us deliver incredible results for our customer’s products. Tags, labels, flexible packaging, folding carton or corrugated packaging—our CTP allows us to produce superb image quality with varying resolutions for any type of packaging need.